Extrusion Chillers

Plastic extrusion processes require chilled water to function correctly. Extruding companies have been turning to WPI for over 25 years for dependable, high efficient, American made chiller systems to cool their processes. Whaley Products has the ability to produce modular chillers, packaged chillers, portable chillers, split chiller systems,glycol chillers, and once through cooling systems.

To determine the size of chiller you’ll need for your plastic process cooling application, follow this formula:

1. Calculate the pounds of material per hour being processed.

2. Determine how many pounds per hour are required for each ton of cooling capacity.

3. Determine if the extruder or any auxiliary equipment will require chilled water.

4. Size the equipment cooling capacity.

5. Combine the process and equipment cooling requirements.

6. Size your chiller by rounding up to the closest standard unit.

**The extruder manufacturer can supply the flow rate through the feed throat and the approximate flow rate to control the barrel in a water-cooled extruder.

| 50# /HR of Polyethylene or Polypropylene | = 1 Ton of cooling |

| 75# /HR of Polystyrene | = 1 Ton of cooling |

| 80# /HR of PVC | = 1 Ton of cooling |

Also to consider:

How much heat supplied by viscous shear heating has to be removed?

Extruder size

Processing temperature window size

Info to size extrusion chiller:

Extruder diameter and length

Number of zones

Extruder hp

Connection sizes

Throughput

Materials being processed

Melt temperature

Cooling required if it is known in either BTU/hr or tons

Packaged Chillers Non-expandable (integrated pump tank) 1.5Ton – 20Ton Single / Dual Circuits Single / Dual Pumps |

SAE Series Modular Chillers Expandable (pump & tank on separate skid) 1.5Ton – 200Ton Single / Dual Circuits |

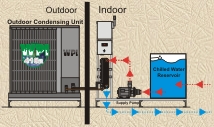

SAR Series Split Chillers Expandable (Outdoor Condensing Unit) (pump, tank, evaporator on indoor skid) 1.5Ton – 200Ton Single / Dual Circuits |